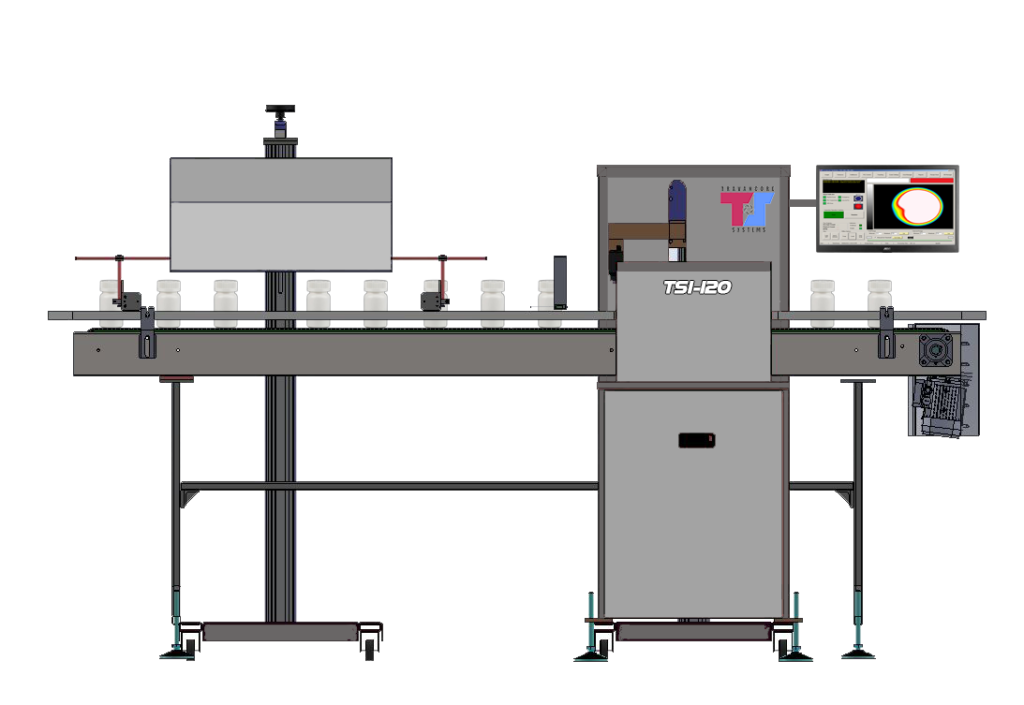

TSi-120 : : Non-Destructive Seal Quality Inspection

TSi-120 was India’s first online induction seal integrity inspection system. We innovated the thermal seal inspection technology.

Using military grade thermal imager and a specially developed analysis algorithm, the system provides 100% inspection accuracy without slowing down your production line. It will help identify the root cause of the sealing problem thereby helping you fix it. TSi-120 comes with a rejection system which has a reject verification system to make sure that the bottle has indeed been rejected. The system can be integrated on all production line with zero disturbance of current setup, it occupies minimal space and runs independently. The software is fully 21CFR Part 11 compliant. Detailed audit and production reports are available.

Checks For :

- Partial Seal

- Burnt Seal

- Missing Foil

- Damaged foil

- Missing cap

- Cold Foil

Technical Specifications

| Sr.No | Parameters | Specifications |

| 1 | System | TSi-120 (seal integrity inspection system) |

| 2 | Max speed | 120 BPM (subject to operational conditions and seal size) |

| 3 | Current | 8.0 AMPS |

| 4 | Power | 230 VAC, Single phase, 50 Hz |

| 5 | Dry compressed air | 3 Kg/cm² ( should be moisture and oil free) |

| 6 | Supply cable | 3 meter x 3 core copper |

| 7 | Container type | HDPE/ PET bottle/containers and glass bottle with HDPE caps only. CRC and Non-CRC, sealing films. |

| 8 | No. of operators required | 01 person |

| 9 | Weight | 160 Kgs for total system |